EF-SERIES™

thermoset powder coatings

OVERVIEW

The functional thermoset powder solution.

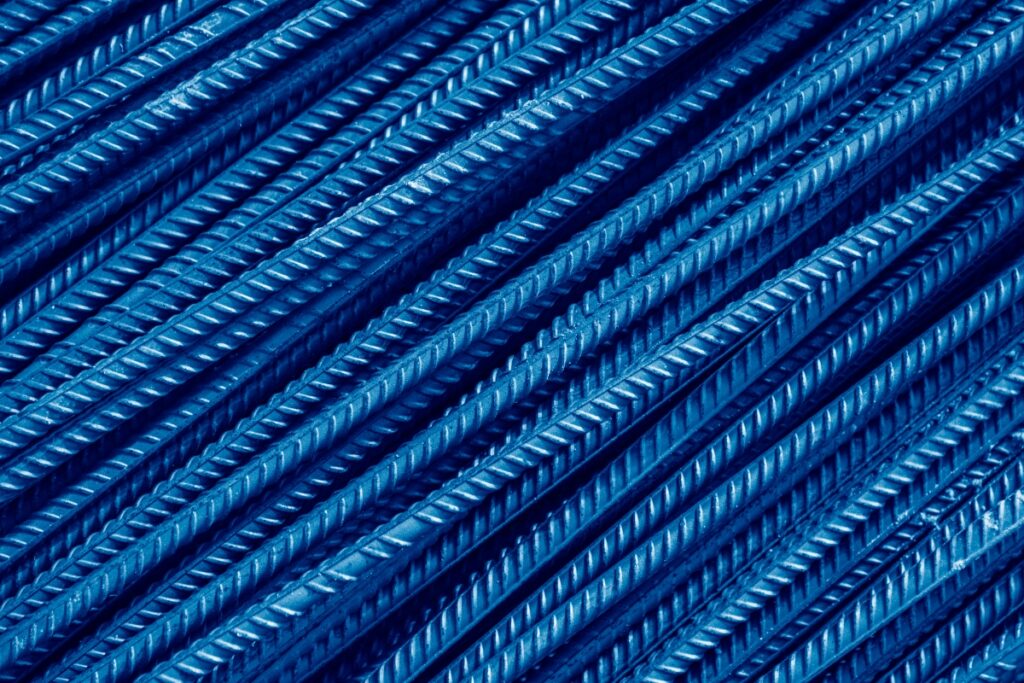

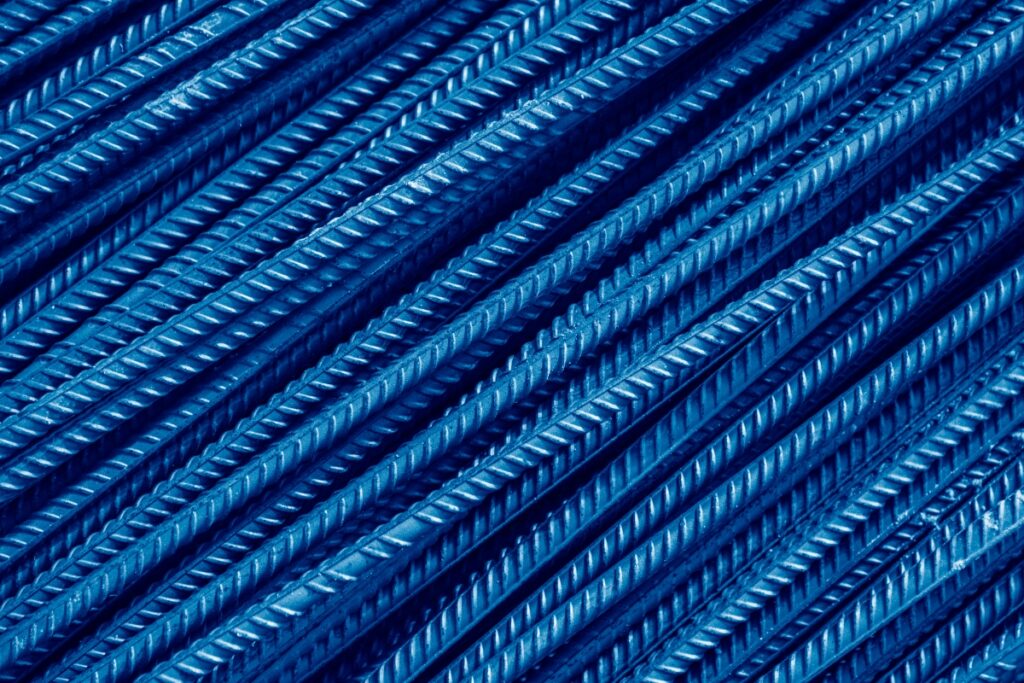

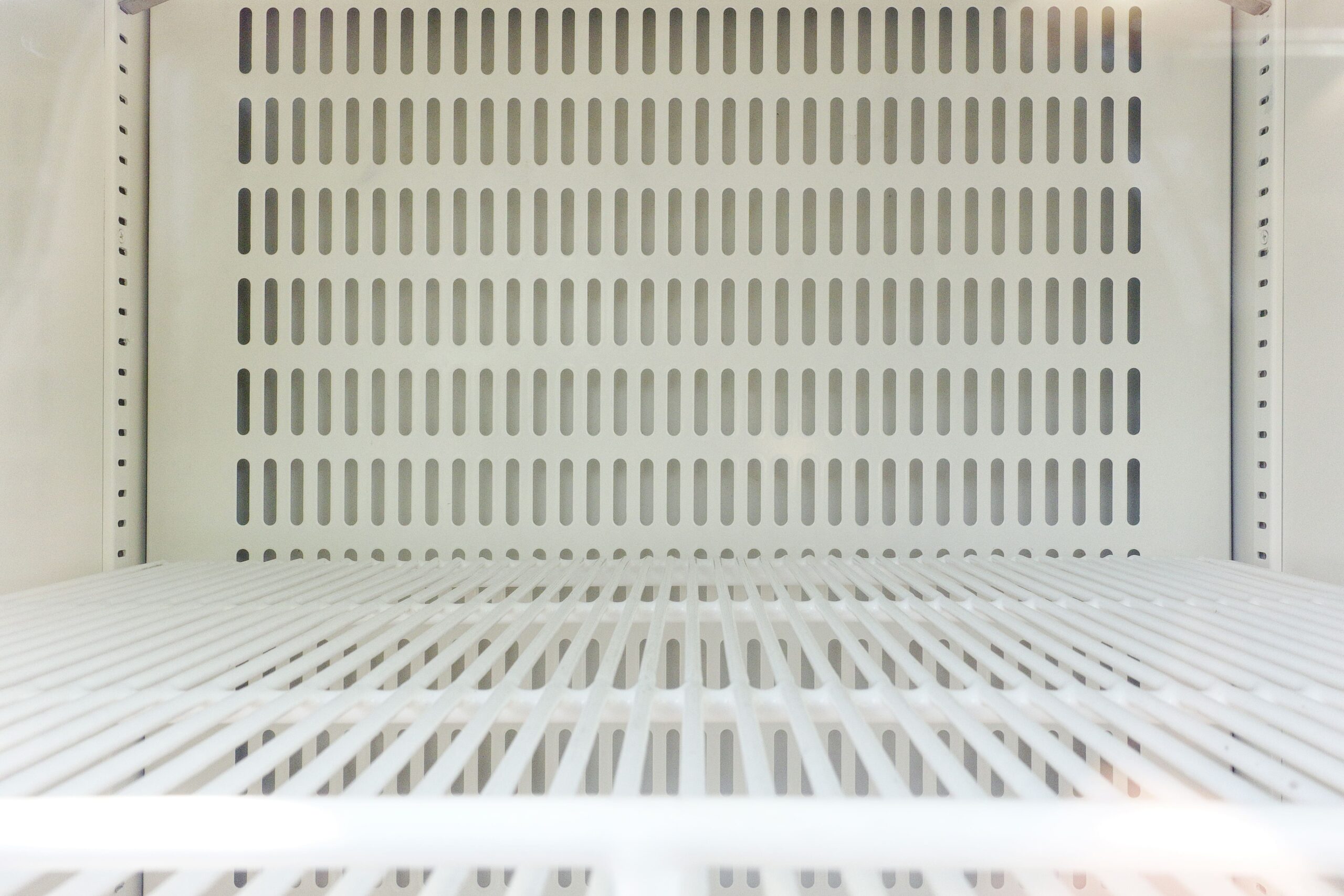

The Protech Group’s EF-SERIES™ is the ideal coating solution for high corrosion and chemical resistant requirements. These powders can be used as a one-coat protective application or as the base coat in a three-coat system. EF-SERIES™ powders are formulated to provide a flexible yet extremely durable finish. These epoxy powders have also proven to provide superior adhesion properties and superior resistance to delamination and cathodic disbondment. EF-SERIES™ conforms to ASTM 775-86 and ASTM 775-89 and has been approved by the U.S. Federal Highway Administration for the protective coating of shotblasted reinforcing bars. EF-SERIES™ is also an ideal application for metal packaging used in the cosmetic, pharmaceutical, chemical and food industries. The powders are completely impermeable prevent-ing the metal packaging from coming into contact with the enclosed contents. EF-SERIES™ coatings are 360º powders which allows a consistent application to the entire inner area of the substrate. They are totally inert powders compliant with global regulatory agencies such as the FDA. EF-SERIES™ demonstrate excellent abrasion and chemical resistance.

MAIN FEATURES

- Superior resistance to cathodic disbondment and delamination.

- Ideal as one coat pipe protection or base for three coat application.

- Excellent chemical and abrasion resistance.

- Highly flexible.

- Excellent adhesion to steel and other potentially oily metallic substrates.

- Ideal application for concrete reinforcing bars and pipes.

- Meets ASTM 775-86 and ASTM 775-89.

- Approved by the U.S. Federal Highway Administration for the protective covering of shot blasted bars.

- Inert coatings compliant with global regulatory agencies (eg FDA) requirements for direct contact.

- Consistent smooth 360 º finish.

- Totally impermeable, coating.

PROVEN PERFORMANCE

| PRE-TREATMENT | For steel and Aluminum–Phosphating or Zirconium or other suitable surface treatment |

| APPLICATION CONDITIONS | Electrostatic powder spray 40 to 100 kv |

| FILM THICKNESS | For normal usage 1.5 to 4.0 mils (Color and finish type related) |

| HARDNESS | HB to 4H (Formulation related) |

| SPECIFIC GRAVITY | 1.2 to 1.75 (Color related) |

| COVERAGE | 160 to 110 ft² / lbs / mil at 100% efficiency (Color related) |

| BAKING SCHEDULE | METAL TEMPERATURE (Formulation Related) 8-10 minutes at 280ºF (138ºC) Super low temperature cure 8-10 minutes at 320ºF (160ºC) Low temperature cure 2-6 Minutes at 400 (205ºC) Fast Cure 7 minutes at 400ºF (205ºC) Regular cure 8+ minutes at 400F (205ºC) Slow cure |

TYPICAL APPLICATIONS

- Pipes

- Rebars

- Valves

- Flexible metal tube packaging

- Potable water systems

- Cosmetic packaging