HELIOCOAT®

thermoset powder coatings

The heat-resistant thermoset powder solution.

OVERVIEW

The heat-resistant thermoset powder solution.

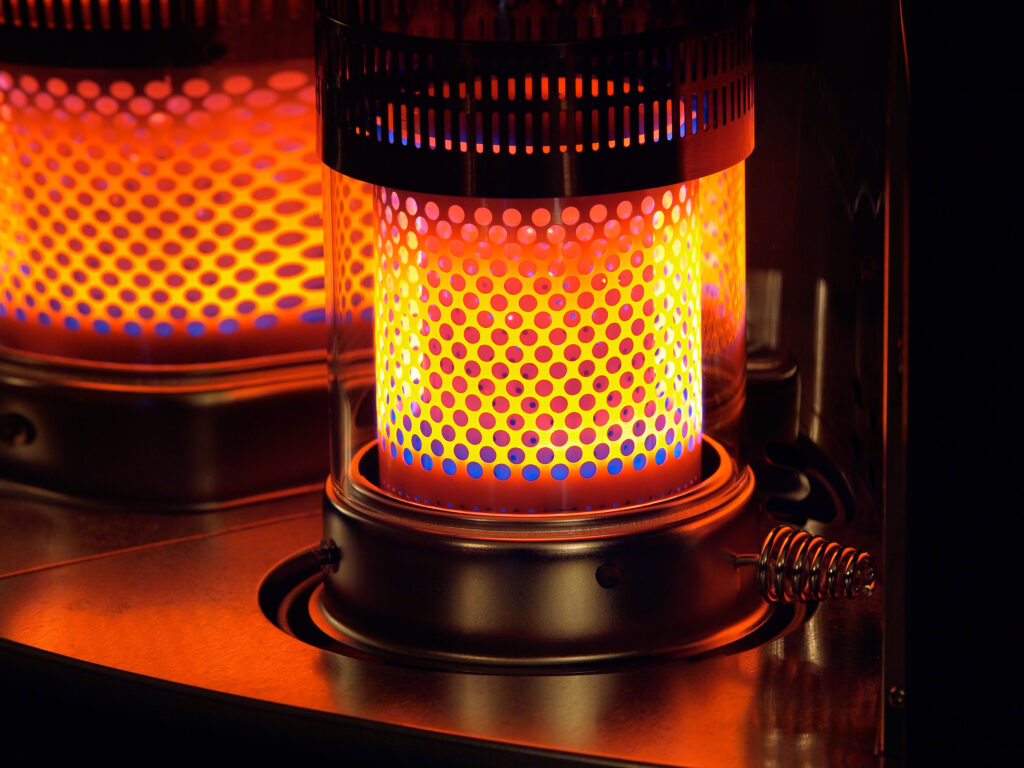

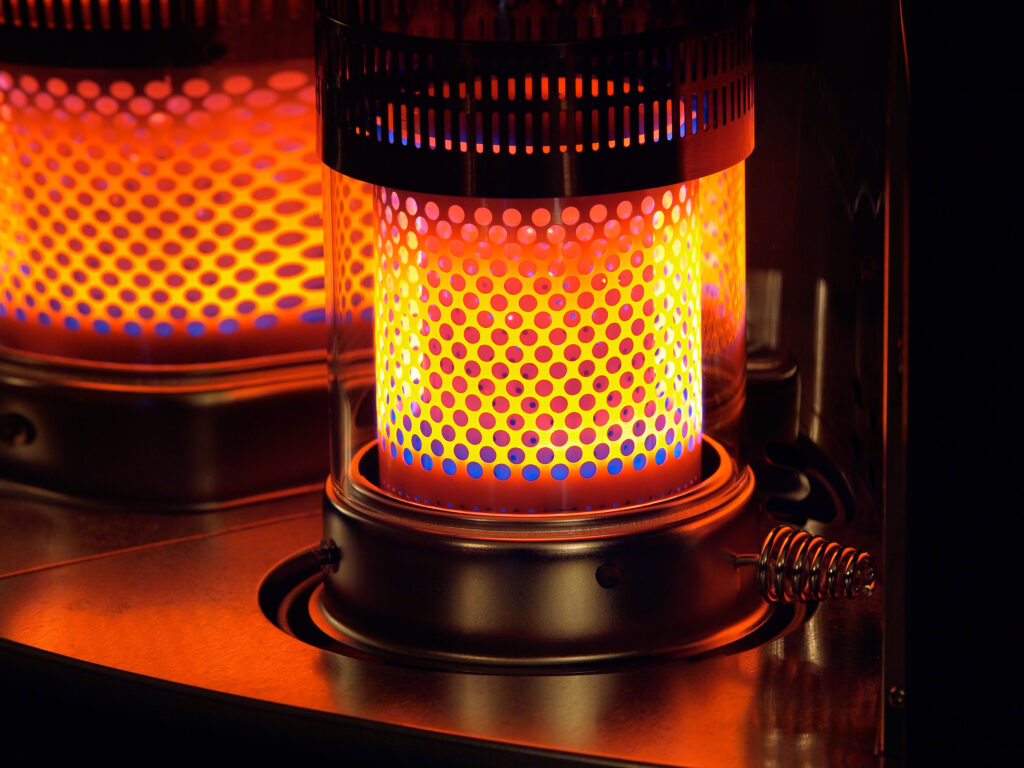

The Protech Group’s ultra high heat resistant HELIOCOAT® can take the heat. Ideal for BBQs, they are available for both interior and exterior applications, with long exposure to constant heat and offer outstanding color and loss stability.

MAIN FEATURES

- Heat resistant up to 900˚F (485˚C).

- Available in outdoor formulations.

- Wide range of colors and textures.

- Excellent chemical, stain and scratch resistance.

- Formulations for continuous heat applications such as baseboard heaters.

- Outstanding color and gloss stability.

- Excellent corrosion and impact resistance.

- Environmentally friendly – no solvent emissions.

PROVEN PERFORMANCE

| CATEGORy 1 350°F – 450°F (177°C – 232°C) | CATEGORY 2 500°F – 600°F (260°C – 316°C) | CATEGORY 3 600°F – 900°F (316°C – 482°C) | CATEGORY 4 > 900°F (> 482°C) | |

|---|---|---|---|---|

| PRIMARY CURE SCHEDULE | 10’ at 400°F (200°C) | 10’ at 400°F (200°C) | 20’ at 450°F (230°C) | 20’ at 450°F (230°C) |

| HARDNESS | H – 2H | H – 2H | H – 2H | H – 2H |

| GLOSS RANGE | 3 – 90° | 3 – 40° | 3 – 40° | 3 – 40° |

| IMPACT RESISTANCE | Up to 160 in.lb | Up to 160 in.lb | Up to 40 in.lb | Up to 40 in.lb |

| TESTS | 24 hours continuous using Blue M convection oven | 12 hours continuous using Thermolyne 1400 furnace oven | 6 hours continuous using Thermolyne 1400 furnace oven | 1 hour continuous using Thermolyne 1400 furnace oven |

TYPICAL APPLICATIONS

- BBQ’s

- Industrial heaters

- Chimney stacks

- Engine casings

- Engine manifolds

- Mufflers

- Light fixtures